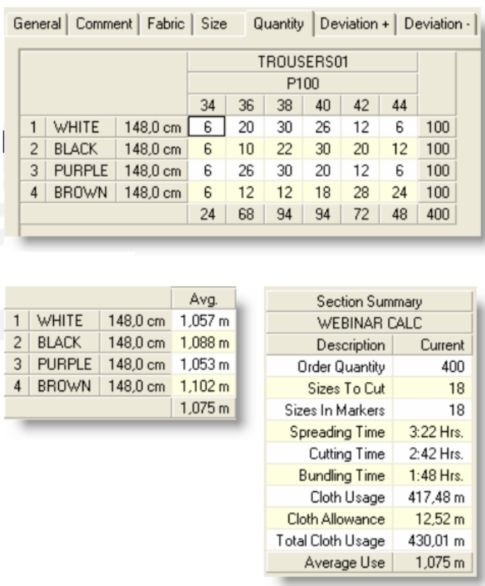

Technology aided decision making in the cutting room ensures lower wastage & increased profits

Apparel Cut plan

Aid decision making on production bulk cutting using decision making tools to optimize fabric consumption, cutting times etc all of which have a direct bearing on your profitability

Optimum combinations

Manually placing patterns has its limitations. Modern CAD tools get higher yields compared to a manual method in a matter of minutes.

Combined with a cut plan and a fabric management system yields optimum results.