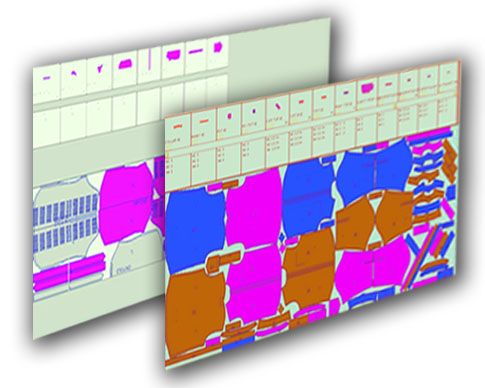

Auto nesting / Marker making helps bring down fabric wastage and quote accurate prices to acquire clients

Marker making

Try infinite placement combinations for every marker to bring down fabric consumption and costs.

Optimize solid , plaids and tubular fabrics

Optimum combinations

Manually placing patterns has its limitations. Modern CAD tools get higher yields compared to a manual method in a matter of minutes.

Combined with a cut plan and a fabric management system yields optimum results.